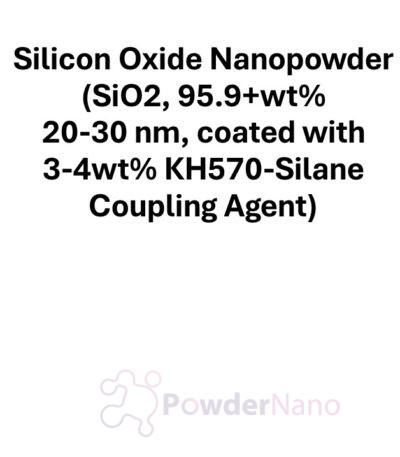

Technical Specifications:

- Chemical Composition:

- Primary Ingredient: Silicon Dioxide (SiO2)

- Purity: 95.9+ wt%

- Coating: 3-4 wt% KH570-Silane Coupling Agent

- Nanoparticle Size:

- Particle Size: 20-30 nm (nanometers)

- Particle Shape: Typically spherical or irregular, depending on the synthesis method and conditions.

- Surface Area:

- The nanopowder possesses a high surface area due to the small size of the particles, which enhances its reactivity, making it suitable for various applications.

- Surface Modification:

- Coating Agent: KH570-Silane Coupling Agent (a different silane agent compared to KH550, with specific functional groups designed to enhance surface interactions).

- Function of KH570-Silane: KH570-Silane is used to improve the dispersion and bonding of the silicon oxide nanopowder with other materials, particularly in organic systems, offering improved stability and surface compatibility.

- Density:

- The nanopowder typically exhibits low density due to the nanoscale size and porous nature of the particles.

- Crystal Structure:

- Amorphous: The silicon oxide is usually in an amorphous state when in nanopowder form, unless subjected to special processing conditions that induce crystallization.

- Other Characteristics:

- Surface Charge: The surface charge may vary depending on the preparation method and pH of the surrounding environment but typically exhibits a negative charge in aqueous solutions.

- Reactivity: Highly reactive due to the large surface area, making it ideal for various chemical reactions and surface modifications.

Applications:

- Nanocomposites:

- Purpose: Silicon oxide nanopowder is utilized to improve the mechanical and thermal properties of composites.

- Application: It is incorporated into polymers, resins, and rubber compounds to enhance strength, stiffness, and thermal stability. The KH570-Silane coupling agent improves the bonding between the inorganic nanoparticles and the organic polymer matrix, enhancing the overall properties of the composite material.

- Coatings and Surface Treatment:

- Purpose: The surface-modified silicon oxide nanopowder improves the performance of coatings and surface treatments.

- Application: It is used in coatings for metal, plastic, and glass substrates to provide enhanced resistance to wear, corrosion, and UV degradation. The KH570 coating enhances adhesion and durability, making it suitable for both industrial and consumer applications.

- Catalysis and Support for Catalysts:

- Purpose: Silicon oxide nanopowder can serve as a support for catalysis due to its large surface area and stability.

- Application: It is used in industrial catalytic processes, including petroleum refining and pollution control. The high surface area allows for the effective loading of metal catalysts, thus improving their efficiency in reactions such as hydrogenation, oxidation, and cracking.

- Drug Delivery and Biomedical Applications:

- Purpose: SiO2 nanopowders are used for controlled drug delivery systems, owing to their biocompatibility and functionalizability.

- Application: The silica nanoparticles can be functionalized with drugs, targeting agents, or imaging agents for biomedical applications such as cancer therapy, gene delivery, and diagnostic imaging. The KH570-Silane coupling agent further helps in achieving specific drug release profiles by modifying the surface properties.

- Electronics and Energy Storage:

- Purpose: Silicon oxide nanoparticles are used to improve the performance of electronic components and energy storage devices.

- Application: They are integrated into lithium-ion batteries and supercapacitors to enhance their charge capacity, cycle life, and overall performance. The silane-coated SiO2 improves the interaction between the nanoparticles and the electrode materials, leading to better charge/discharge efficiency.

- Environmental Remediation:

- Purpose: The highly reactive surface of silicon oxide nanopowder is useful in environmental applications for adsorption and remediation.

- Application: It is employed in water treatment, air filtration, and soil decontamination. The nanopowder adsorbs contaminants, including heavy metals, organic compounds, and pollutants, making it an effective tool for cleaning up hazardous materials in the environment.

- Sensors and Detection Devices:

- Purpose: Due to its large surface area, silicon oxide nanopowder is used in various sensors and detection systems.

- Application: It is used in gas sensors, chemical sensors, and biosensors for detecting gases like CO2, NOx, or volatile organic compounds (VOCs). These sensors are essential in environmental monitoring, industrial safety, and healthcare diagnostics.

- Cosmetic and Personal Care Products:

- Purpose: SiO2 nanoparticles are used for their smooth texture and ability to absorb moisture in cosmetic formulations.

- Application: Silicon oxide nanopowder is incorporated into products like foundations, sunscreens, and powders for its ability to provide a smooth finish, absorb excess oil, and enhance the product’s skin feel. It is also used as a thickening agent in formulations.

Key Benefits:

- Improved Dispersion: The KH570-Silane coupling agent ensures better dispersion of silicon oxide nanoparticles in organic matrices, enhancing material properties such as adhesion and stability.

- High Reactivity: The small size and high surface area of SiO2 nanoparticles increase their reactivity, making them ideal for applications in catalysis, sensing, and environmental remediation.

- Versatile Applications: Silicon oxide nanoparticles have diverse applications across industries like electronics, healthcare, environmental science, and material science.

- Enhanced Mechanical Properties: When used in composites, the addition of SiO2 nanoparticles improves mechanical properties like strength, flexibility, and durability.

- Biocompatibility: The high purity and surface modification with silane agents make these nanoparticles suitable for biomedical and pharmaceutical applications.